REUSABLE MODULAR ABS FORMWORK FOR SQUARE AND RECTANGULAR COLUMNS

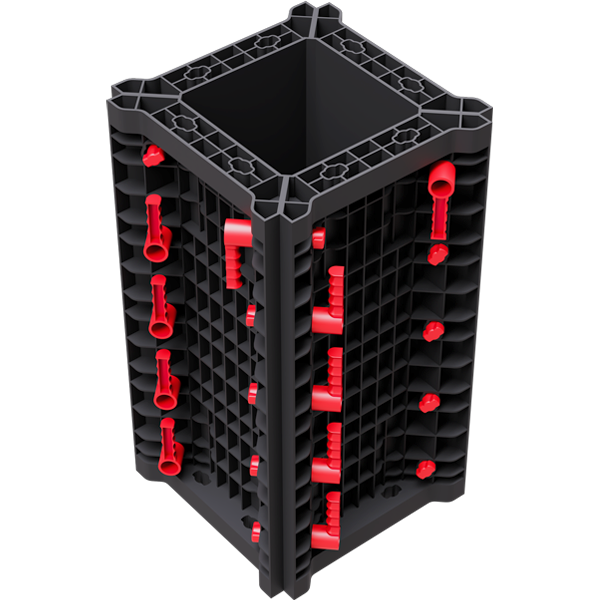

GEOTUB® PANELLO is the first modular formwork made of UV-resistant plastic designed for casting square and rectangular columns.

This modular formwork system is highly adaptable and can be easily configured to suit any project.

ADVANTAGES OF USING GEOTUB PANELLO®

LIGHTWEIGHT

Weighing only 8 kg, GEOTUB PANELLO® can be easily moved around the construction site without cranes or mechanical equipment.

It is lightweight and easy to assemble, allowing installation by a single worker.

MODULAR DESIGN

All elements have a standard height of 750 mm.

No cutting or adjustments are required — assembly is done using only the necessary components for each specific project.

REUSABLE

GEOTUB PANELLO® is cost-effective and can be reused more than 100 times, ensuring substantial savings compared to traditional systems.

EASY REMOVAL

Concrete does not adhere to the plastic surface, allowing for easy stripping and cleaning using only water — no oils or cleaning agents are needed.

STORAGE

The GEOTUB® PANELLO system can be fully disassembled and stored even in humid environments without damage or deformation.

EASY HANDLING ON SITE

Due to its compact dimensions, the formwork can be easily transported and assembled wherever required on site.

RESULT

Columns cast with GEOTUB PANELLO® have a smooth, high-quality concrete surface, which can be left exposed without additional finishing.

INSTALLATION AND REMOVAL

All components are connected with durable nylon handles.

Installation and removal are quick and simple, using handles that ensure secure locking with a 90° turn.

Both the panels and handles can be mounted in any direction, offering full flexibility during assembly.

TECHNICAL TABLE OF PLASTIC MODULAR FORMWORK AND ITS ELEMENTS

| GEOTUB PANEL MODULAR FORMWORK WITHSTANDS UP TO 60 kN/M² |

| GEOTUB PANEL 55 combinations |

| Product |

Actual size (mm) |

Material |

Weight (kg) |

Number of handles |

Price €/pcs. |

| GEOTUB PANEL 20 |

200 x 750 x 60 |

ABS |

3,25 |

6 |

54 |

| GEOTUB PANEL 23 |

230 x 750 x 60 |

ABS |

3,63 |

7 |

56 |

| GEOTUB PANEL 25 |

250 x 750 x 60 |

ABS |

3,67 |

7 |

58 |

| GEOTUB PANEL 30 |

300 x 750 x 60 |

ABS |

3,97 |

7 |

63 |

| GEOTUB PANEL 35 |

350 x 750 x 60 |

ABS |

4,84 |

8 |

68 |

| GEOTUB PANEL 40 |

400 x 750 x 60 |

ABS |

5,32 |

8 |

71 |

| GEOTUB PANEL 45 |

450 x 750 x 60 |

ABS |

6,09 |

8 |

78 |

| GEOTUB PANEL 50 |

500 x 750 x 60 |

ABS |

6,56 |

9 |

85 |

| GEOTUB PANEL 55 |

550 x 750 x 60 |

ABS |

7,14 |

9 |

95 |

| GEOTUB PANEL 60 |

600 x 750 x 60 |

ABS |

7,49 |

9 |

107 |

| ACCESSORIES |

| Lever |

|

Naylon |

0,10 |

|

3,43 |

TECHNICAL SPECIFICATIONS OF THE MODULAR PLASTIC FORMWORK:

-

Dimensions: Modular element with a standard height of 750 mm

-

Waterproofing: 100% waterproof

-

Storage: Does not require special storage conditions

-

Load capacity: Withstands pressure up to 60 kN/m²

-

Cement adhesion: Concrete does not stick to the panel because it is made of plastic

-

Protection: Provides optimal protection for the column until the completion of construction works

-

Vertical installation: Quick installation thanks to the external structure that ensures easy anchoring and precise vertical positioning of columns

-

Release agents: Not required

DOWNLOAD / VIEW CATALOGS

|

Geotub Panel - Manual

|

Formwork Solutions EN - Catalogue

|

GEOPLAST 2022 - Catalogue

|

|

|

|

|

With its dimensions—75 cm high and 20 to 60 cm wide—the plastic modular formwork can be used in 45 combinations. Panels are connected using nylon handles until the maximum column height of 3 meters is reached.