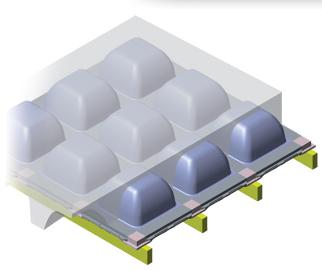

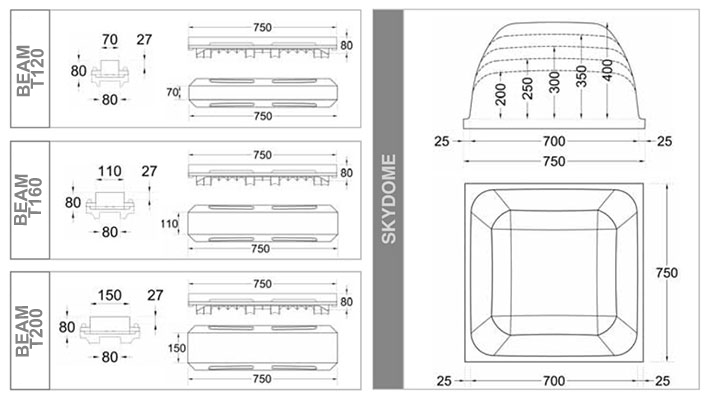

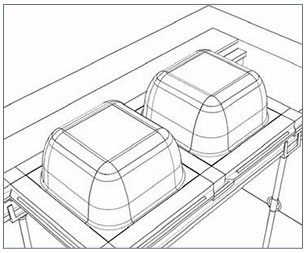

Skydome System – Modular Coffered Slab Formwork

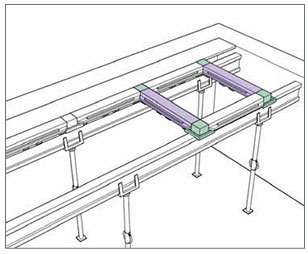

The Skydome coffered slab formwork system allows for a reduction in overall slab thickness while increasing the span between columns or load-bearing walls.

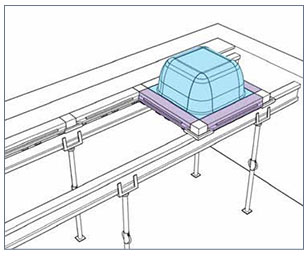

Using Skydome significantly reduces reinforcement and concrete consumption compared to other slab formwork systems.

ADVANTAGES OF USING THE SKYDOME COFFERED SLAB SYSTEM

ECONOMY

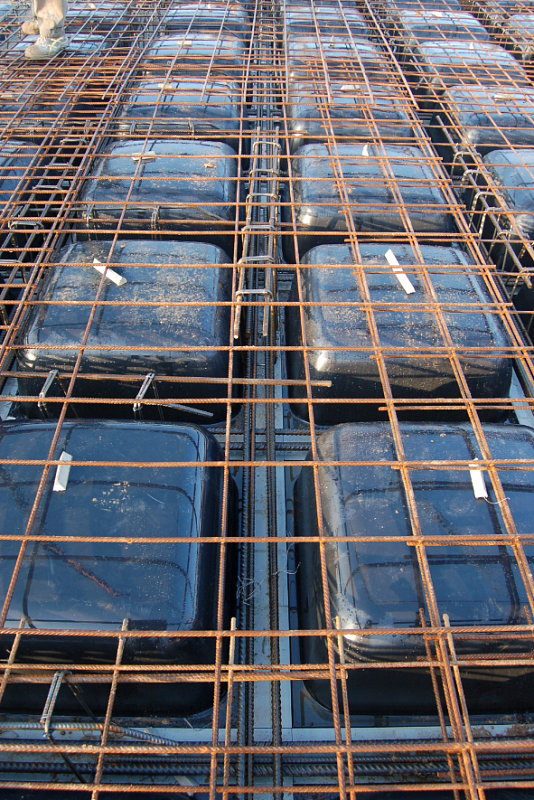

The voids created by the Skydome formwork lead to substantial concrete savings compared to traditional solid slabs.

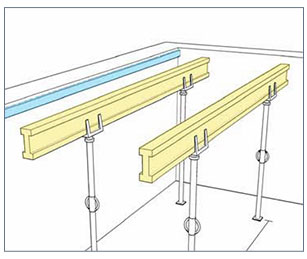

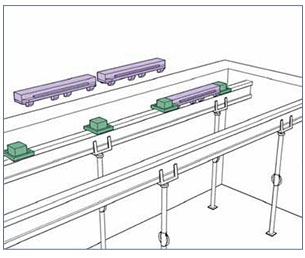

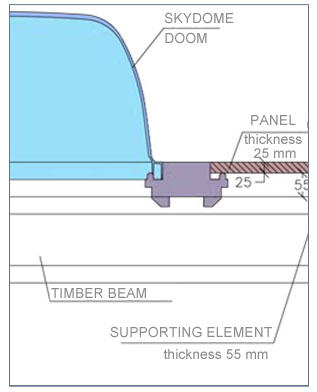

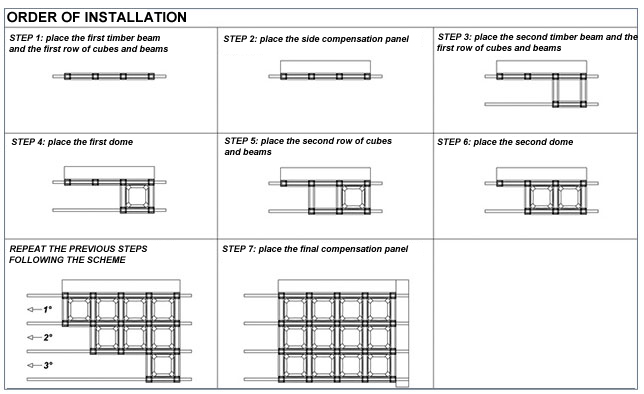

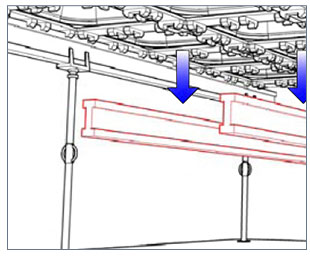

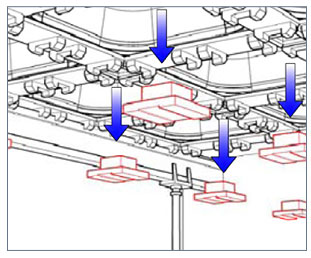

Skydome can be easily installed on H20 timber beams, eliminating the need for other shoring or scaffolding systems.

SAFETY

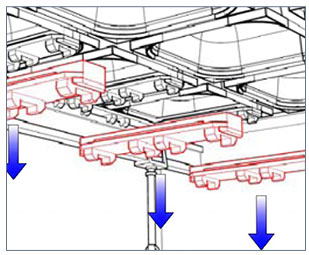

Skydome is a self-supporting system, requiring no additional supports or safety structures.

It can be assembled from below, ensuring maximum worker safety during installation.

TECHNOLOGY

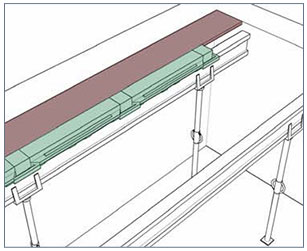

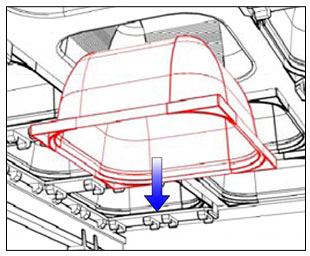

The dome-shaped forms of Skydome make it possible to create two-way waffle slabs with large spans, ensuring maximum structural efficiency due to the reduced self-weight of the slab.

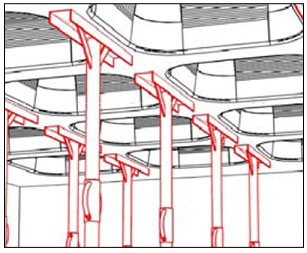

DISMANTLING

Concrete does not adhere to the plastic surface, so stripping is fast and easy without the use of release agents.

All elements can be cleaned simply with water.

REUSABILITY

Thanks to its durable material and design, Skydome can be reused more than 100 times, offering long-term cost efficiency.

HANDLING

The material is very lightweight, allowing for quick removal and relocation on site without cranes.

Skydome can be stored in confined or even humid spaces without any degradation.

RESULTS

Slabs made with Skydome can be left exposed for an architectural finish or covered with a suspended plasterboard ceiling.

SUSTAINABILITY

The Skydome system is made entirely from recycled plastic, making it an environmentally friendly solution.