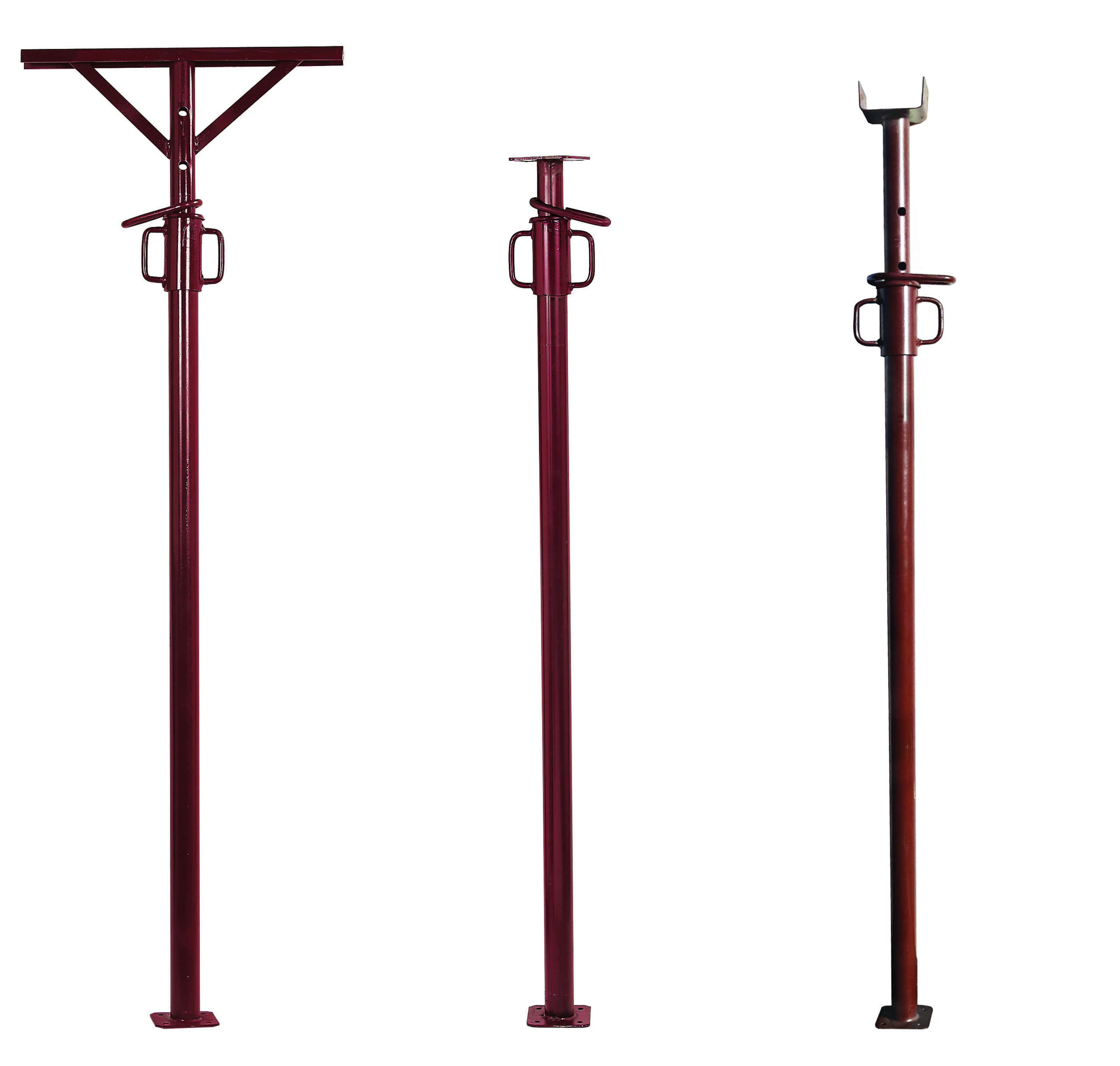

TELESCOPIC PROP “STANDARD”, ITALIAN TYPE, WITH CLOSED THREAD

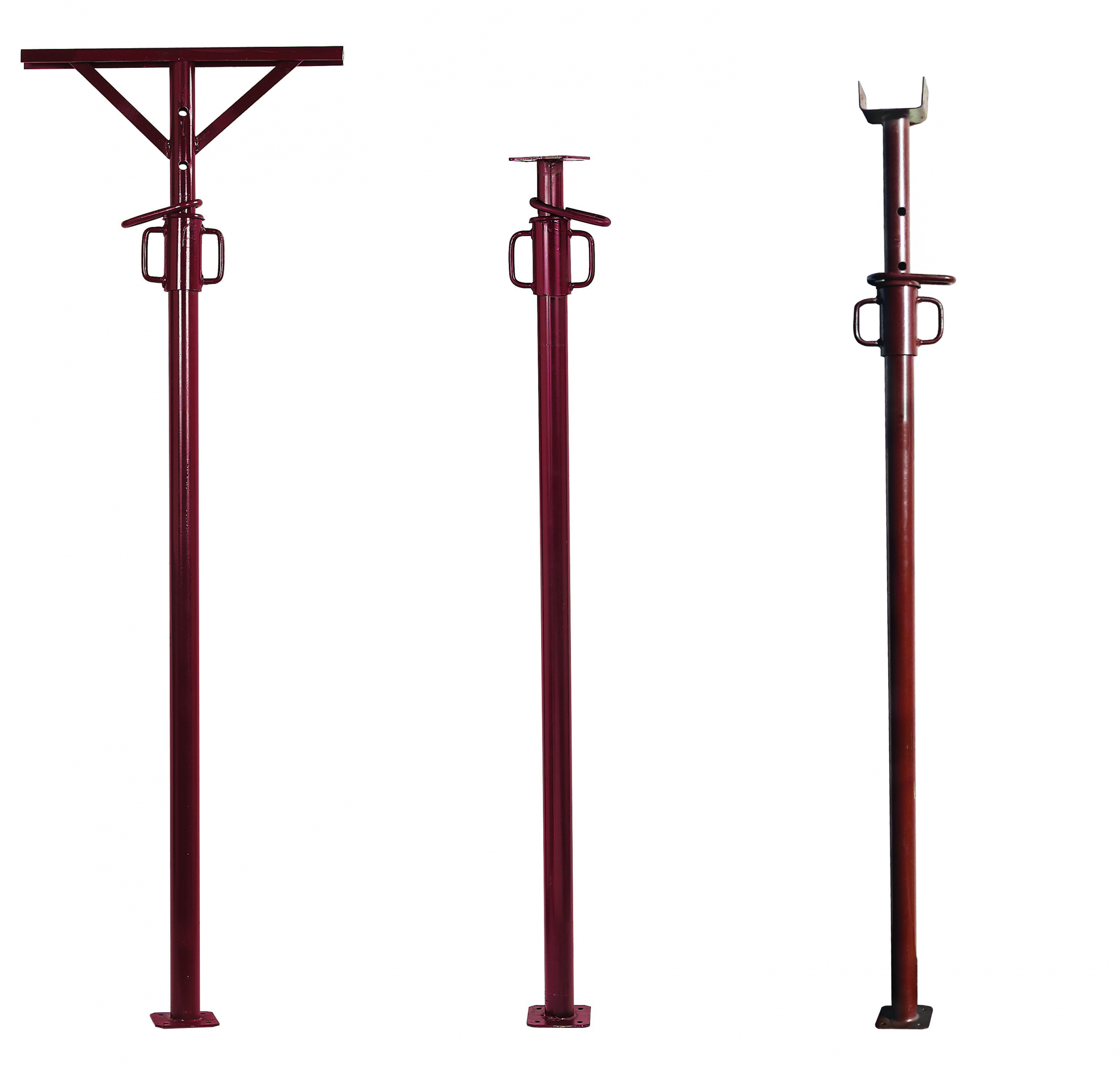

Available in the following sizes (cm): 180/320, 200/360, 250/440, 320/500.

Thanks to its cost-effectiveness, lightness, and strength, the two-plate “Italian standard” prop is the most well-known and widely used support both in Italy and on international markets.

It can meet any load-bearing requirement up to a maximum extension of 5.50 m in height and can be combined with most accessories used in formwork systems.

Supplied as standard in brown color RAL 8015; on request, it can be manufactured with hot-dip galvanization according to UNI EN ISO 1461, Standard UNI EN 40.

Sold in packages of 50 units.

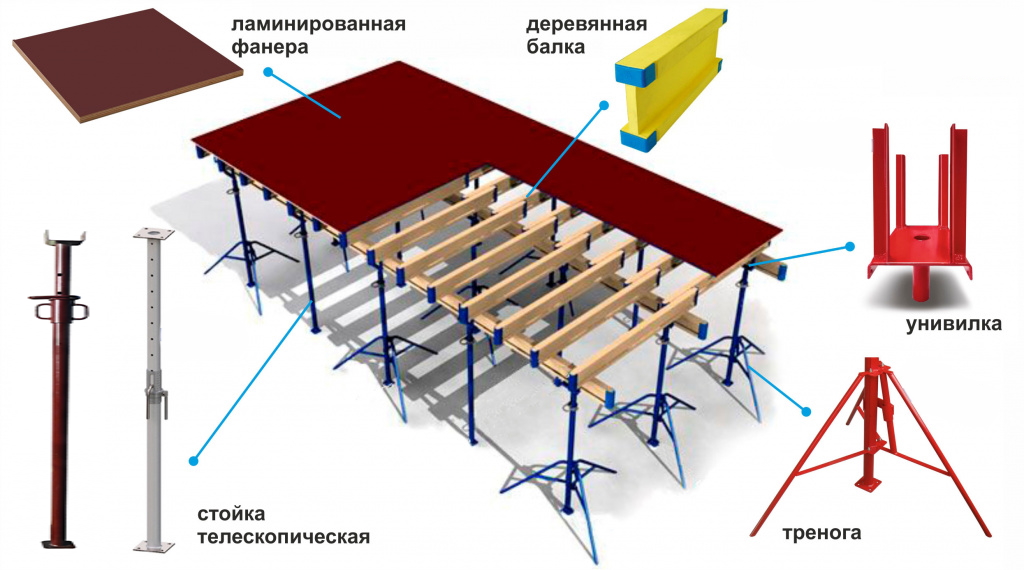

Application

The telescopic prop is used as a supporting element in beam-and-prop slab formwork systems. The props are equipped with fork heads (U-heads) on which H20 beams are placed and with tripods for better stability.

TELESCOPIC PROP “STANDARD”, ITALIAN TYPE, WITH CLOSED THREAD

FEATURES:

-

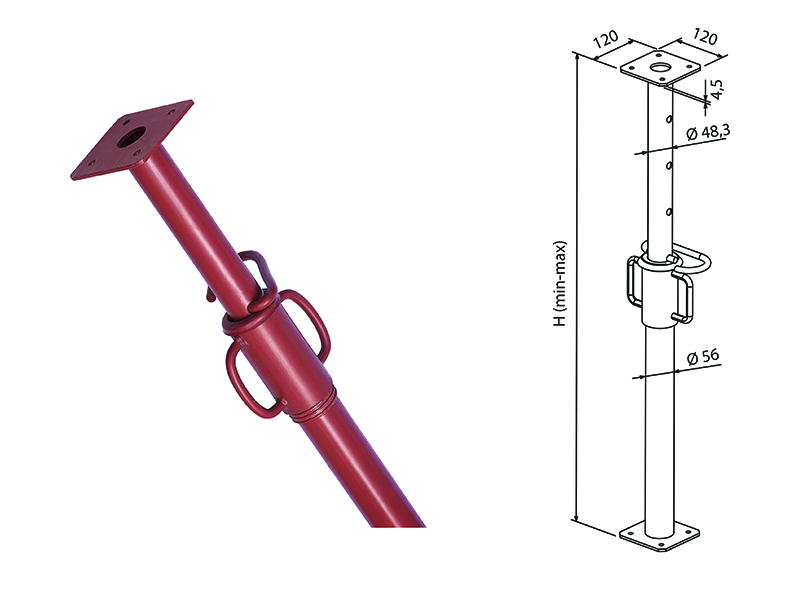

Steel tubes: S235JRH grade.

-

Threaded sleeve: welded to the outer tube, manufactured by a rolling process that ensures maximum geometric precision, stability, and higher load-bearing capacity.

-

Inner tube: drilled every 100 mm for height adjustment.

-

Nut (collar): length 135 mm, with an 8 mm thread pitch and welded handles.

-

Safety pin: Ø14 mm, used to secure the connection between the inner and outer tubes.

-

Sliding washer and nut protection for smooth operation and durability.

-

Base and top plates: flat plates 120×120×4.5 mm for optimal load distribution.

-

Anti-slip system ensuring maximum safety.

-

Manufactured in accordance with: UNI EN 729-2:1996 standards.

| ITALIAN-STYLE TELESCOPIC ADJUSTABLE STANDS WITH CLOSED THREAD |

|

Standard sizes |

180/320 |

200/360 |

220/400 |

250/440 |

260/480 |

320/500 |

| СМ |

kg |

kg |

kg |

kg |

kg |

kg |

| 500 |

|

|

|

|

|

300 |

| 480 |

|

|

|

|

350 |

400 |

| 440 |

|

|

|

550 |

600 |

650 |

| 420 |

|

|

|

750 |

800 |

800 |

| 400 |

|

|

758 |

900 |

900 |

1 000 |

| 380 |

|

|

890 |

950 |

1 050 |

1 200 |

| 360 |

|

801 |

980 |

1 010 |

1 200 |

1 400 |

| 340 |

|

1 091 |

1 150 |

1 190 |

1 320 |

1 600 |

| 320 |

870 |

1 215 |

1 230 |

1 300 |

1 400 |

1 800 |

| 300 |

1 071 |

1 280 |

1 300 |

1 420 |

1 480 |

|

| 290 |

1 190 |

1 385 |

1 450 |

1 500 |

1 600 |

|

| 270 |

1 346 |

1 509 |

1 630 |

1 580 |

1 700 |

|

| 250 |

1 540 |

1 640 |

1 700 |

1 700 |

|

|

| 230 |

1 660 |

1 750 |

1 750 |

|

|

|

| 220 |

1 740 |

1 764 |

1 800 |

|

|

|

| 200 |

1 785 |

1 800 |

|

|

|

|

| 180 |

1 800 |

|

|

|

|

|