This metal structure is designed to move various loads within its rated lifting capacity.

It is used for lifting and transporting loads up to 16 tons.

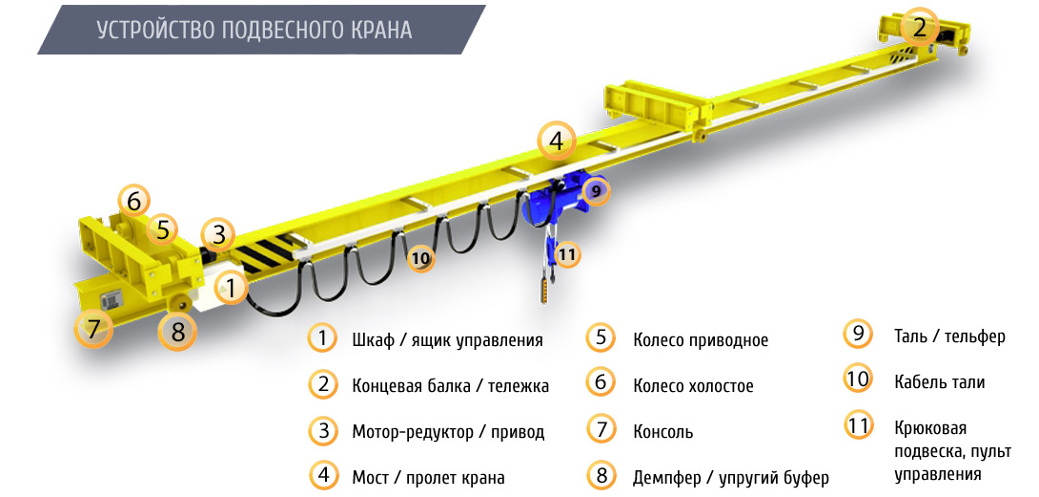

The crane consists of main girders (made from I-beams) and three end carriages, each equipped with motor-gear units that drive the crane’s motion.

Power is supplied by an electric cable or another suitable system.

The crane is operated via a wired control pendant with an emergency stop button, with optional radio control or operator cabin control available for greater comfort and safety.

The lifting and moving mechanism is an electric hoist (trolley) that travels along the crane’s span.

The load-lifting component is a hook suspension attached to a wire rope.

A distinctive feature of this design is that the underslung crane is mounted beneath the runway beams.

An additional end trolley is attached to a central guiding beam located between the two spans, providing enhanced structural stability and reliability.

For improved safety and operational convenience, various optional features can be installed.

This crane type is widely used in manufacturing facilities for maintenance, assembly, and loading/unloading operations.

Its primary advantages are versatility and full coverage of the working area within the production space.