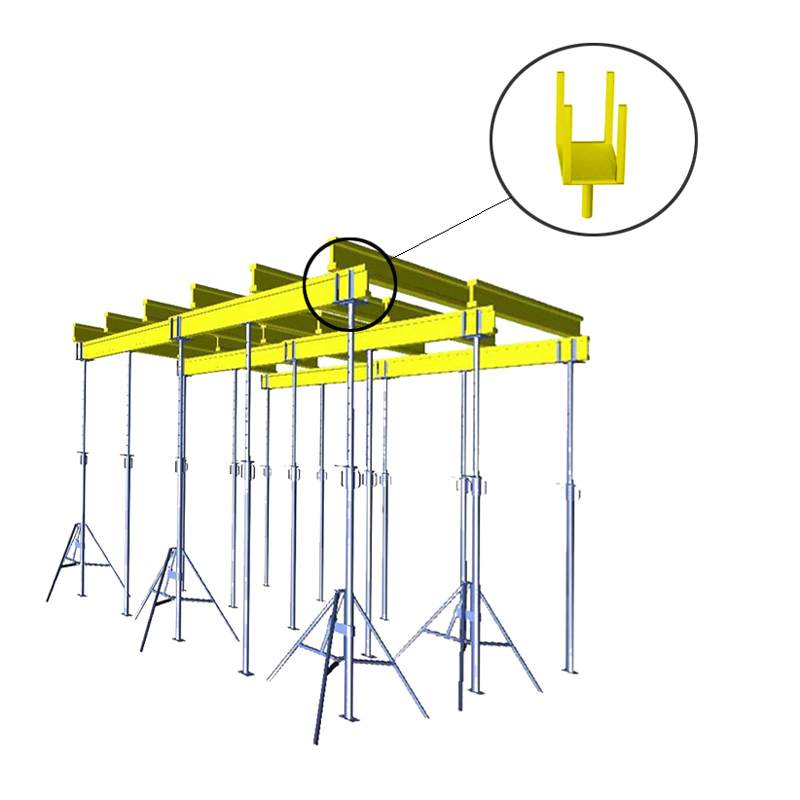

U-HEAD (UNIVERSAL FORK)

The U-head, or universal fork, is a special accessory designed to securely hold beams at the top end of vertical telescopic or modular props used in slab formwork systems.

It ensures that the beam remains firmly fixed in position, preventing any lateral displacement during operation.

Additionally, the U-head allows for the reliable connection and alignment of beams at the point where the vertical prop is positioned, ensuring stability, safety, and precision in the assembly of the formwork structure.

U-HEAD (UNIVERSAL FORK) — CONSTRUCTION AND SPECIFICATIONS

The design of the U-head (universal fork) must comply with GOST 5254-80-U4.

The welded steel construction of the U-head consists of the following elements:

-

A rectangular metal plate (2) measuring 244 × 154 mm, welded to a steel tube (3) with an outer diameter of 38 mm.

-

On the opposite side, four vertical steel angle sections or square tubes (1) are welded to the corners of the plate. Each has a 32 mm side and a height of 170 mm.

This configuration creates a U-shaped fork (“crown”), with a 90 mm gap between the vertical “horns” along the plate’s width — allowing a standard H-beam used in slab formwork systems (with a base width of 80 mm) to fit freely between them.

Installation and Use

The U-head assembly is mounted by inserting the tube base onto the top pin of a telescopic prop. It is then secured with a locking pin inserted into a lateral through-hole with a diameter of 15.5 mm.

The formwork beam rests on the top plate of the U-head and is held securely on both sides by the vertical “horns.”

The distance between the horns along the plate’s length is 170–180 mm, allowing two beams to be positioned tightly side by side.

This design enables overlapping (lap joint) connections between beams, ensuring strong, stable, and precise alignment within the formwork system.

U-HEAD (UNIVERSAL FORK) — FEATURES AND ADVANTAGES

Some U-heads (universal forks) feature “horns” made of steel angles with holes for screws, allowing wooden beams to be fixed directly to the angles for enhanced stability and safety.

The standard installation method of the U-head in a slab formwork system is illustrated in the final photo of the reference documentation.

Advantages of the U-Head Design

-

Simplicity and reliability:

A robust and rigid welded structure that ensures durability under heavy loads.

-

Lightweight construction:

The U-head weighs only 1.9–2.0 kg, making it easy to handle and transport on-site.

-

Quick and easy installation/dismantling:

The design allows for fast assembly and removal, significantly reducing setup time for slab formwork systems.

-

Versatility:

Can be used both as part of slab formwork systems and in scaffolding structures — for facade, finishing, and repair works.

-

Multi-purpose functionality:

Suitable for supporting beams, as well as for their alignment, connection, and extension, offering maximum flexibility in various construction applications.