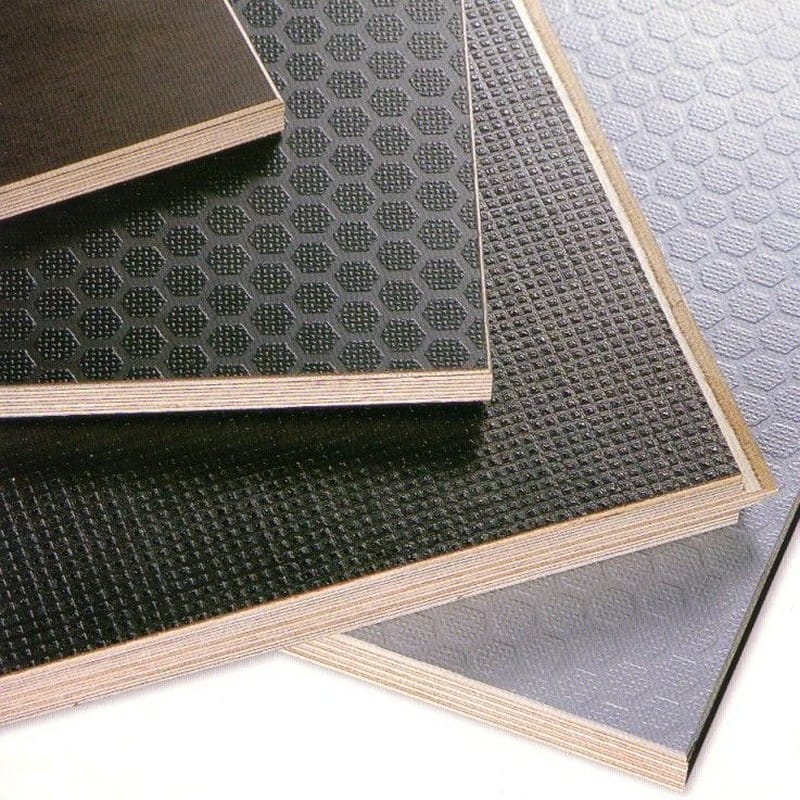

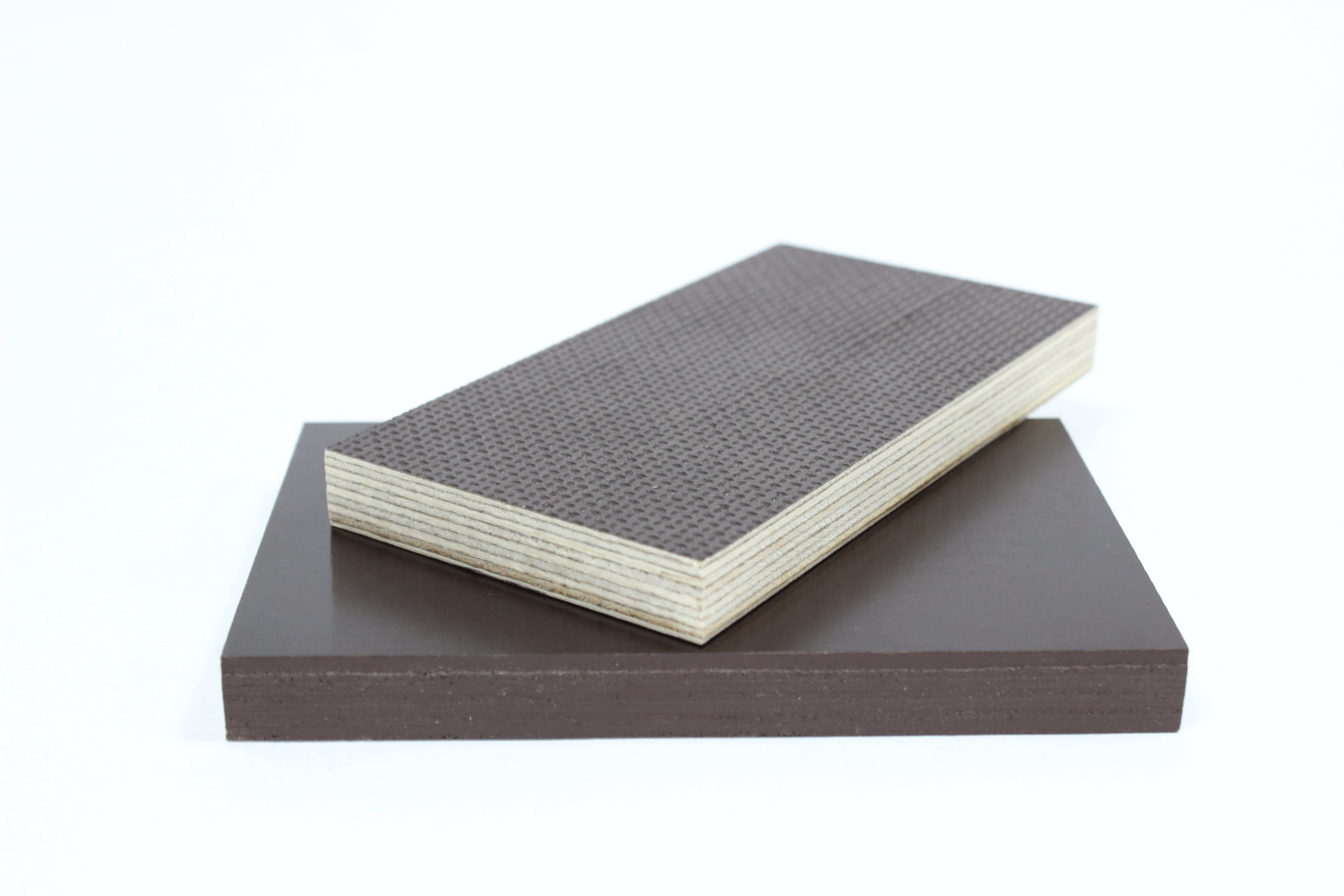

LAMINATED PLYWOOD FSF DARK BROWN WITH MESH is high-quality birch FSF plywood, coated with a special material—paper impregnated with phenolic resins, which during the manufacturing process acquires the properties of a protective film. The edges of the plywood are protected by waterproof paint. Thanks to this, the surface of the material is resistant to moisture, abrasion, chemicals, and the formation of fungus and mold.

The mesh-laminated surface of the plywood (ANTISLIP mesh) is convenient for use in the transportation industry for flooring, warehouse and factory floors, loading platforms, i.e., where increased wear resistance and anti-slip properties are required.

Advantages: • ANTI-SLIP SURFACE

• EXCEPTIONAL STRENGTH AND WEAR RESISTANCE

• ENHANCED WATER RESISTANCE

| Laminated Plywood with anti-slip embossing (F/W) |

| Dimensions (Length x Width) |

2500 х 1250мм |

|

| Thicknesses |

6, 9, 12, 12,5, 15, 18, 19, 20, 21, 24, 27, 30, 32, 35мм |

| Film Color |

Dark brown with logo |

| Film Density |

120 g/м2 |

| Edge Treatment |

Waterproof paint |

| Formaldehyde Emission Class |

E1 |

| Glue Type / Water Resistance |

FSF with increased water resistance |

| Density |

640-680 kg/м3 |

| Moisture Content |

5-7% |

| Grades |

1, 1/2 |

| Core |

100% birch |

| Surface Type |

Smooth (F/F |

Thickness (mm) and Number of Layers (pcs) laminated ANTI-SLIP

6.0, 9.0, 12.0, 12.5, 15.0, 18.0, 19.0, 20.0, 21.0, 24.0, 27.0, 30.0, 32.0, 35.0

REFERENCE INFORMATION

|

Water resistance:

- FSF (increased)

- FC (standard)

Formaldehyde emission class: E1

Moisture content: 5-12%

|

Dimensional tolerance:

Shear strength:

Tensile strength along the fibers:

|

Flexural strength under static load along the fibers of the outer layer:

Number of usage cycles in monolithic construction:

Friction coefficient measured according to DIN 51130

|