DOUBLE-ACTION PROPS (“PUSH-PULL” TYPE)

The push-pull props are a derivative of Class B props, retaining all their safety features and load-bearing capacity.

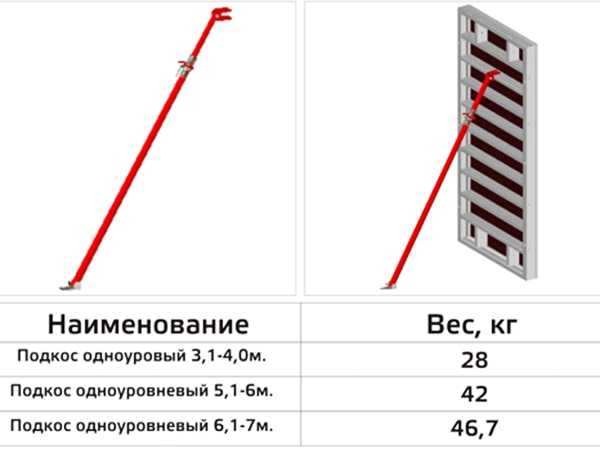

These props are designed to work under both compression and tension, offering a cost-effective solution for installing vertical formwork systems and timber panels, ensuring their stability during concrete pouring.

They are also widely used in pre-assembly operations, where they provide reliable support for vertical wall elements during installation.

Technical Specifications

-

Inner/outer tubes: made of S235JRH steel, according to UNI EN 10219-1/2.

-

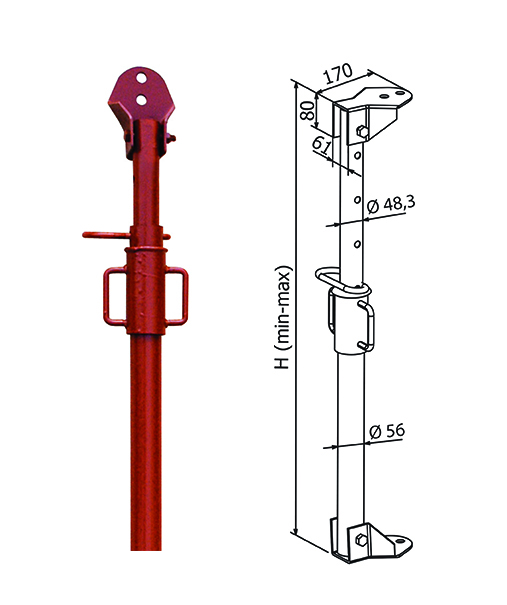

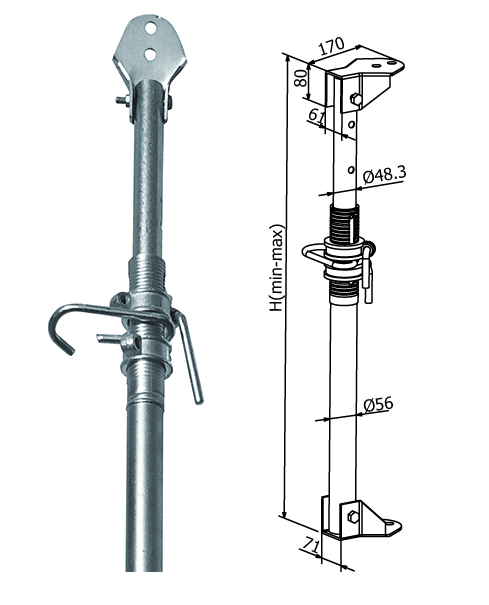

Inner tube: Ø48.3 mm

-

Outer tube: Ø57 / Ø60.3 mm

-

-

Adjustment system: either with collar or external self-cleaning nut.

-

Non-removable pin with chamfered end for secure locking.

-

Maximum extension: from 2600 mm to 5100 mm.

Features

-

Round hinged bases:

Equipped with oval holes that make positioning safer and easier during installation. -

Safety system:

When fully closed, the prop ensures at least 10 cm of free inner-tube length, preventing accidental hand injuries from compression. -

Perforated holes:

Burr-free machining guarantees smooth operation and full functionality even after repeated use. -

External thread:

Produced by rolling (not cutting), ensuring material integrity. The long thread length allows for fine height adjustment and includes two self-cleaning round steel nuts for easy operation. -

Internal thread:

Also rolled, then welded to the outer tube, ensuring high strength and reliability. -

“Push-pull” steel coupling:

The upper section of the tube provides the push-pull effect, while simultaneously protecting the internal thread. The deformation at the lower end prevents accidental detachment from the thread.