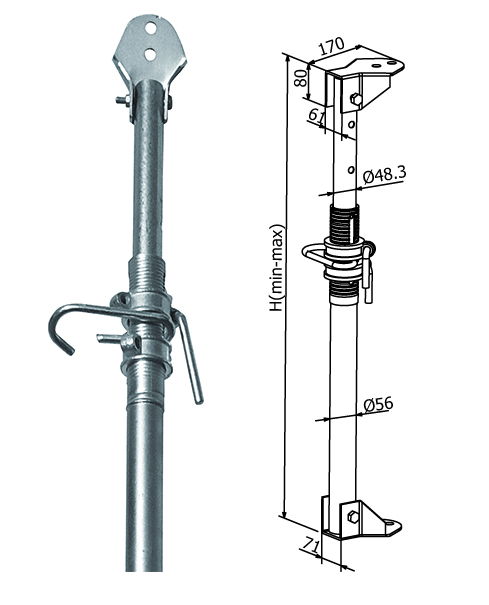

TWO-LEVEL TELESCOPIC “PUSH-PULL” PROP

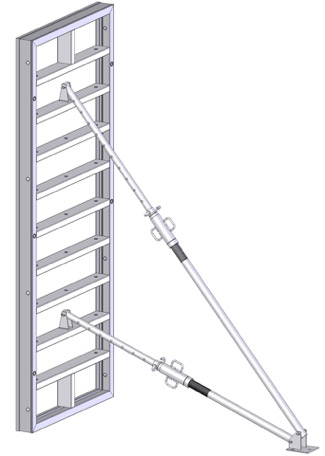

The two-level telescopic push-pull prop is designed to support formwork panels in a vertical position and to adjust their alignment with high precision.

Its telescopic design, consisting of inner and outer steel tubes, allows for a wide range of length adjustment, providing smooth, reliable, and accurate positioning of formwork structures in full accordance with project requirements.

Initial adjustment of the panels is performed by extending the inner tube of the prop and connecting it to the formwork panel using a special anchoring platform.

For fine alignment, a threaded mechanism with a flanged nut is used.

The upper joints of the props are connected to the formwork panels, while the lower ends are securely anchored to the concrete base using bolts or anchors.

These props operate under both compression and tension, providing a cost-effective and safe solution for the installation and stabilization of vertical formwork systems — whether timber, steel, or prefabricated panels.

They are also successfully used in pre-assembly applications, ensuring the stability of vertical walls during construction and installation.

Technical Specifications

-

Inner/outer tubes: made of S235JRH steel, according to UNI EN 10219-1/2

-

Adjustment system: collar or external self-cleaning nut

-

Non-removable pin: with chamfered tip for secure locking

-

Maximum extension: from 2600 mm to 5100 mm

Key Features

-

Round hinged bases:

Feature oval holes that make positioning safer and installation easier.

-

Safety system:

When fully closed, at least 10 cm of the inner tube remains visible, preventing accidental hand injuries during compression.

-

Perforated holes:

Precisely machined and burr-free, ensuring smooth operation and long-term functionality even after repeated use.

-

External thread:

Rolled (not cut) for maximum strength and durability. The long thread length allows fine height adjustment and includes two self-cleaning round steel nuts.

-

Internal thread:

Also rolled, then welded to the outer tube, providing greater strength and functional reliability.

-

Steel “push-pull” coupling:

The upper section of the tube creates the push-pull effect and protects the internal thread, while the lower deformation prevents accidental disconnection from the thread.

TP PROPS (PUSH-PULL TYPE)

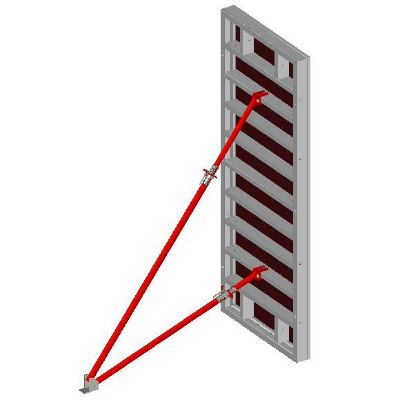

TP props, also known as Pull-Push or Push-Pull props, are double-action telescopic supports capable of operating under both compression and tension.

These systems are essential for securing and stabilizing a wide range of structures with maximum safety during the concreting phase.

They provide an effective and economical solution for installing vertical formwork systems, whether timber, steel, plastic, or prefabricated panels of various types.

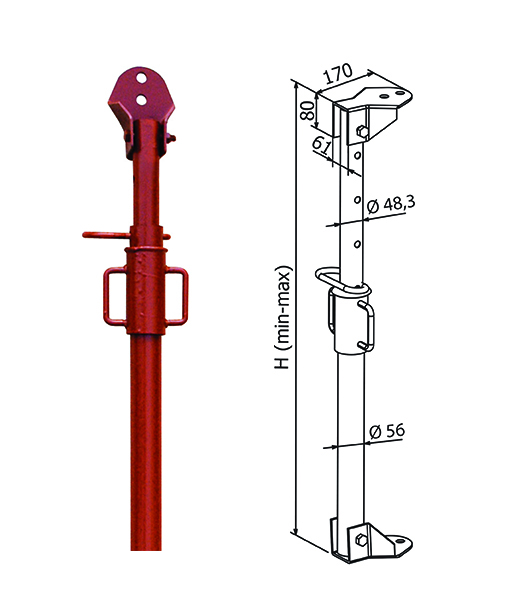

Available Versions

-

Standard version:

Equipped with a hinged and 45° tiltable base plate for easy positioning and alignment.

-

Class B version:

Incorporates all the safety and load-bearing characteristics of heavy-duty Class B props, also featuring a hinged and 45° tiltable base plate.

-

Double-hinged version:

Designed with a dual hinge system to ensure precise and secure attachment to steel formwork structures.

Technical and Manufacturing Features

-

Coating:

Painted using the immersion method, providing corrosion resistance compliant with ASTM D2247-87 humidity chamber test standards.

Color: Brown RAL 8015.

-

Welding:

Performed in accordance with the qualified welding procedure certification (WPQR) following DIN EN ISO 15613:2005.

Certificate No.: P16W.0122.

-

Production standards:

UNI EN 729-2:1996

-

Steel quality:

S235 JRH, ensuring excellent mechanical performance, structural integrity, and durability.

| Code |

Extension (H) /m |

Weight /Kg |

Loading capacity / kN (1 kN = 102 Kg) |

| min |

max |

Compression |

Traction |

| H min |

H max |

| TP 180/320 |

1,80 |

3,20 |

10,50 |

13,87 |

17,85 |

17,85 |

| TP 200/360 |

2,00 |

3,60 |

11,80 |

7,96 |

17,85 |

17,85 |

| TP 220/400 |

2,20 |

4,00 |

13,60 |

8,51 |

17,85 |

17,85 |

| TP 250/440 |

2,50 |

4,40 |

14,90 |

7,65 |

17,85 |

17,85 |