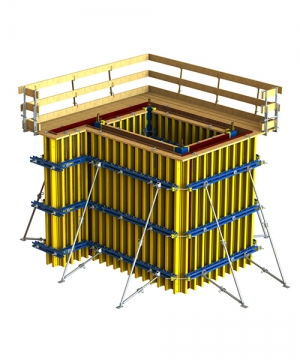

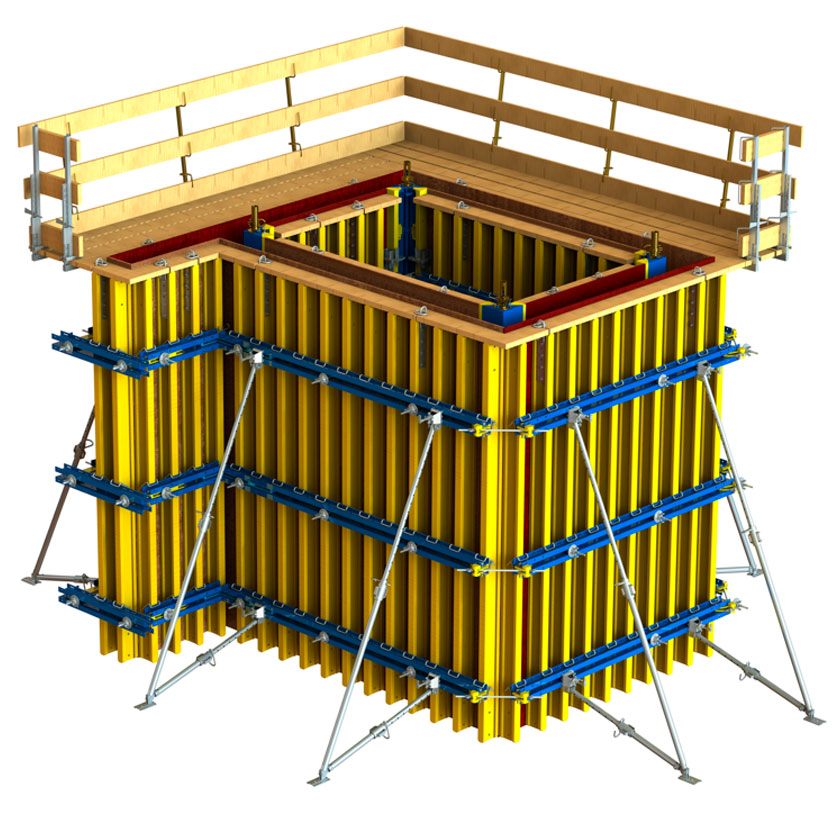

Easily adaptable system

The easily adaptable system helps meet any design requirements involving cast-in-place concrete. Vertex 60 can be used on various types of projects and construction sites — from simple straight walls and complex cross-sections of columns in residential and high-rise buildings to the construction of bridges, tunnels, and more. In addition, it can also be used as formwork panels in single-sided or climbing systems.

Load-bearing capacity

Thanks to its operational flexibility, Vertex 60 is designed and assembled to withstand virtually any pressure from freshly poured concrete (recommended range — 30 to 70 kN/m²).

The most cost-effective approach in terms of price and formwork spacing is a permissible pressure of 40 kN/m² for freshly poured concrete.

Cost efficiency

-

Convenient execution of large concrete surface areas;

-

High number of reuse cycles reduces subsequent costs;

-

Reduced expenses due to the system’s operational flexibility;

-

High-quality concrete surfaces minimize finishing work;

-

Adaptable to each individual project, allowing for any type of form design required.

Ease of use and planning

-

All connectors and accessories are freely inserted into grooves and quickly tightened, enabling efficient construction and maximum productivity;

-

The system’s load-bearing capacity can be adjusted using H20 beams and steel girders;

-

The system’s flexibility allows it to meet any design requirements involving cast-in-place concrete.

Safety in use

Lifting hooks, concreting brackets, push-pull props, and other accessories ensure the safety and ease of use of the system.

Application areas of the Vertex 60 system

-

Large-area wall formwork;

-

Column formwork;

-

Single-sided formwork systems;

-

Bridge and tunnel construction;

-

Climbing formwork systems.