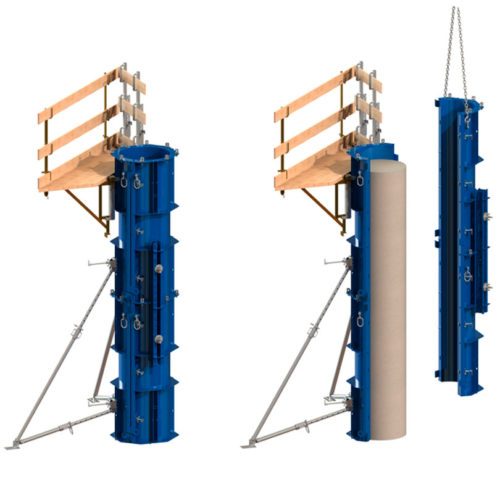

Circular Column Formwork SK 100 is designed for constructing columns with a circular cross-section.

For the creation of curved or oval-shaped columns, the SK 100 system can be combined with Varimax and Ringform circular formwork.

The system consists of semi-circular formwork panels with standard diameters ranging from 30 cm to 130 cm in 10 cm increments.

The semi-circular elements are connected using built-in connectors — no additional fastening components are required.

Panels are available in three standard heights: 50 cm, 100 cm, and 200 cm, which can be stacked vertically to achieve any desired column height.

High-strength formwork

Permissible pressure of freshly poured concrete:

-

Up to D = 600 mm — 150 kN/m²

-

Up to D = 800 mm — 100 kN/m²

-

Up to D = 1300 mm — 80 kN/m²

Ease of use and planning

-

Only three standard panel heights and eleven standard diameters (in 10 cm increments) make planning and assembly simple;

-

Custom diameters up to 200 cm available upon client request;

-

All connectors are integrated, and accessories easily fit into grooves and tighten quickly, ensuring efficient construction and maximum performance.

Cost efficiency

-

Fast concreting process;

-

Preassembled blocks minimize crane use;

-

When using only two semi-circular sections per column, assembly and stripping times are optimized;

-

High reusability reduces long-term costs;

-

Quick cleaning lowers maintenance expenses;

-

Powder-coated steel construction extends the system’s service life;

-

High-quality concrete surface minimizes finishing work requirements.

Safety in use

Concreting brackets, push-pull props, and other accessories ensure the safety and ease of operation of the system.