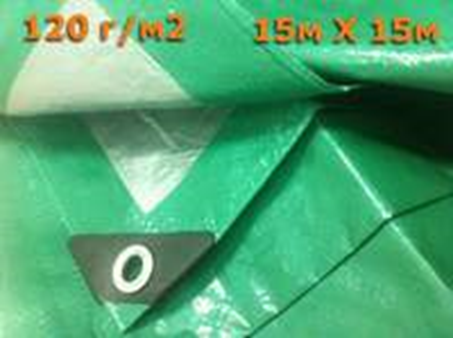

Tarpaulin 120 g/m² is a universal covering material widely used in construction, agriculture, transportation, and tourism. The lightweight yet durable tarpaulin fabric features metal eyelets along the edges, spaced at 1-meter intervals, allowing easy fastening with ropes around the perimeter or partially, depending on the application.

The raw material for manufacturing construction tarps is polyethylene. A dense fabric with reinforced edges is made by weaving polymer threads into a sheet, which is then laminated to obtain a light- and waterproof surface. The protective material is resistant to tearing and mechanical deformation. Thanks to UV-stabilizing additives, reinforced tarpaulin sheets retain their properties throughout their service life.

Tarpaulins 120 g/m² are designed for use in temperatures from -40°C to +50°C and have UV stabilization for up to 2 years.

Applications:

-

Covering construction materials from rain, snow, or hail

-

Creating temporary shelters or worksite canopies

-

Covering scaffolding, roofs, and window openings

-

Protecting agricultural machinery, vehicles, trailers, and cargo

-

Lining pools, artificial ponds, or tanks

-

Covering agricultural products (grain, feed, hay, etc.)

-

Setting up tents, waterproof mats, and outdoor shelters for tourism

Advantages:

-

Resistant to UV radiation

-

Waterproof and vapor-impermeable

-

High mechanical strength

-

Light-impermeable

-

Long-lasting durability

In case of damage, a patch can be applied or the cut area sealed. The flexibility and softness of the material, even at subzero temperatures, ensure reliable protection of objects of any size from precipitation.