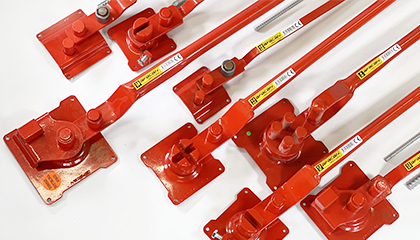

2. MANUAL REBAR BENDING MACHINE – AFACAN

The Afacan manual rebar bending machine is a specialized tool designed for cold bending of round, square, and flat steel bars. It provides precision, reliability, and ease of use, making it an essential instrument for reinforcement and metalworking tasks on construction sites and in workshops.

Purpose and Application

Manual Afacan bending machines are intended for bending reinforcement bars in cold conditions, ensuring accurate bends without damaging the metal structure. They are commonly used in reinforcement fabrication, formwork assembly, and general metalwork operations.

Model Range and Specifications

The Afacan rebar bending machine lineup includes 7 models, each suited for different rebar diameters and working conditions:

-

Bending capacity: from 6 mm to 16 mm in diameter

-

Lever length: from 940 mm to 1430 mm, depending on the model

-

Operation type: manual, with a lever arm providing mechanical advantage for smooth, effortless bending

Advantages

-

Versatile use: suitable for round, square, and flat steel.

-

Cold bending operation: ensures precision without compromising the structural integrity of the material.

-

Simple and ergonomic design: easy to use, requiring no special training or power supply.

-

Portable and durable: ideal for both on-site and workshop applications.

-

Available in multiple models: allowing users to select the most suitable machine based on bar diameter and working requirements.

The Afacan manual rebar bending machine combines robust construction, ergonomic handling, and versatility, making it a reliable and efficient tool for professional reinforcement and construction work.

Before using the manual machine, it should be secured to a stable horizontal surface using screws or bolts. For a better understanding of how to operate the Afacan manual rebar bending machine, we recommend watching the video:

3. ADVANCED METHODS OF REBAR BENDING

Professional rebar bending is carried out using electric bending machines, which greatly increase efficiency, simplify workflow, and allow bending operations at an industrial scale.

Such machines are ideal for large enterprises engaged in the production of reinforced concrete elements, specialized rebar fabrication plants, and construction sites with sheltered working areas.

In private construction with small work volumes, a manual rebar bending machine is usually sufficient.

For optimal performance, the manual bender should be securely fixed to a workbench or frame using self-tapping screws or bolts — these ensure stability during bending operations.

⚠️ Important: Never weld the machine to the surface — it must be fastened only with screws or bolts.

Manual Key or Bending Machine — Which to Choose?

The choice depends on the stage and scale of work:

-

The rebar bending key is used for rebars already embedded in concrete, enabling precise adjustments during or after installation.

-

The manual rebar bending machine is used during reinforcement preparation, before installation into the structure.

Thus, for small-scale or private construction, manual tools are fully sufficient, while for industrial or large-scale projects, electric machines provide higher productivity and consistency.

Purpose of Rebar Bending

Bent reinforcement bars are widely used in reinforced concrete construction, especially in structural connection points — such as corners and joints — which are typically the most vulnerable areas.

Creating corners or intersections by simply overlapping straight bars is a violation of construction technology. Instead, continuous bent rebars should be used, shaped according to design specifications.

Why Only Cold Mechanical Bending Should Be Used

Improper methods often used in home construction — such as notching the rebar before bending or heating it with a torch — seriously weaken the steel and reduce its strength characteristics.

According to construction standards, rebar must be bent cold and only by mechanical means.

This approach preserves the original physical and chemical properties of the steel, ensuring durability and safety of reinforced concrete structures.

Conclusion

Both rebar bending keys and manual bending machines are indispensable for achieving accurate, safe, and durable reinforcement configurations.

Their use guarantees compliance with construction standards and provides structural integrity — whether in private building projects or industrial-scale reinforced concrete production.