WOODEN I-BEAM FOR FORMWORK (H20 TYPE)

The H20 wooden I-beam for formwork consists of two solid wooden flanges (top and bottom) and a central web made of a three-layer board, all joined together using toothed and glued joints for maximum structural integrity.

These H20 beams are a key element in the construction of horizontal formwork systems. They are characterized by exceptional strength, high load-bearing capacity, dimensional stability, and resistance to deformation.

Manufactured mainly from carefully selected, kiln-dried softwood, the beams are water-resistant, with surfaces coated in synthetic resin, ensuring long service life and durability even under demanding site conditions.

Produced in compliance with EN 13377 standards.

Advantages

-

Dimensional stability and recovery after loading.

-

High load-bearing capacity maintained along the entire beam length.

-

Resistance to moisture, impact, and chipping for extended durability.

-

Lightweight and easy to handle, allowing fast assembly and dismantling.

-

Low weight for convenient manual installation.

-

Perfect compatibility with three-layer formwork panels.

-

Can be cut at any point and supported anywhere along its length, offering flexibility in formwork design.

-

Universal use — suitable for all types of formwork systems.

-

Long service life — when used according to operational recommendations, H20 beams can last for several years with a minimum of 30 reuses.

A standard formwork beam measures 80x40x200 mm, where 80 mm is the shelf width, 40 mm is the shelf thickness, and 200 mm is the total height of the I-beam (for H20). The standard length can range from 2.5 to 5.9 m.

| Wooden beam for formwork H20 |

| Material of the upper and lower shelves |

The spruce wood is calibrated, with rounded and protected edges and finger joints along the entire length. |

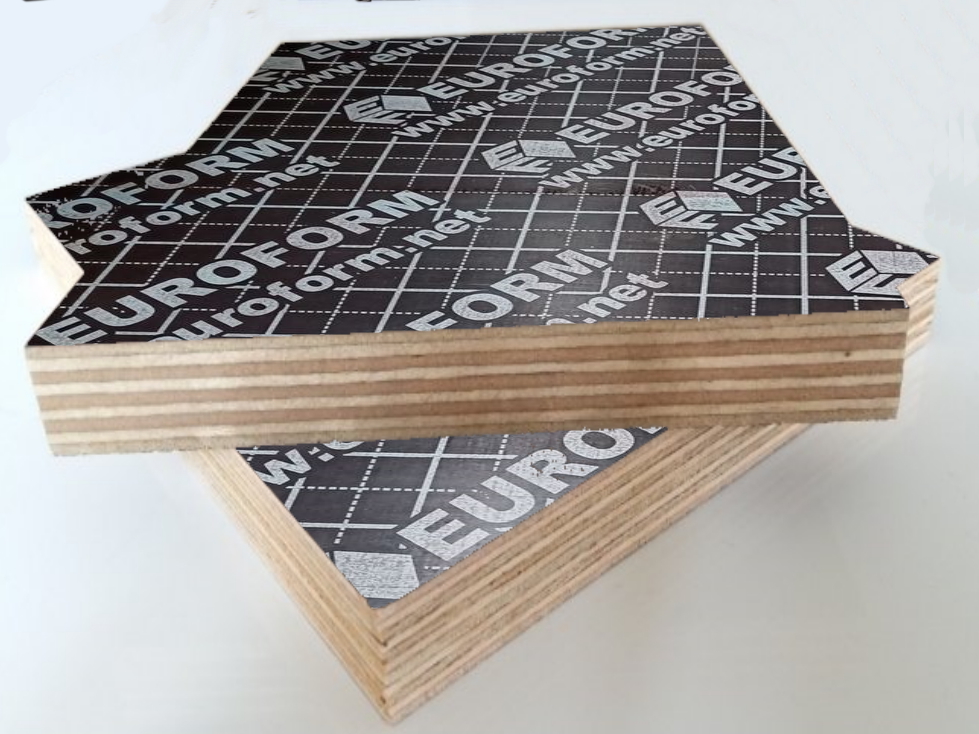

| Wall material |

Three-layer panel, 27 mm thick. |

| Surface |

The surface of the beam is covered with synthetic resin, which ensures a long service life of the beams and protection from moisture, impacts and chips. |

| Gluing |

Bonding with melamine glue under controlled conditions of temperature and pressure. |

| Ends |

The ends, which are the most vulnerable point, are reinforced with special plastic caps. |

| Permissible bending moment: |

M = 5,0 kN/m. |

| Permissible shear force |

Q = 11,0 kN |